The comparison between expanded metal sheets and perforated metal sheets is paramount when we select our materials for many applications in architectural, industrial, or decorative projects, so it is crucial to do this as it allows all engineers, designers, and builders to select the most appropriate option to suit and fit their desired aesthetic needs and structural solidity as those expanded metal sheets and perforated metal sheets are widely applied in exterior and interior systems and in addition to ventilation designs.

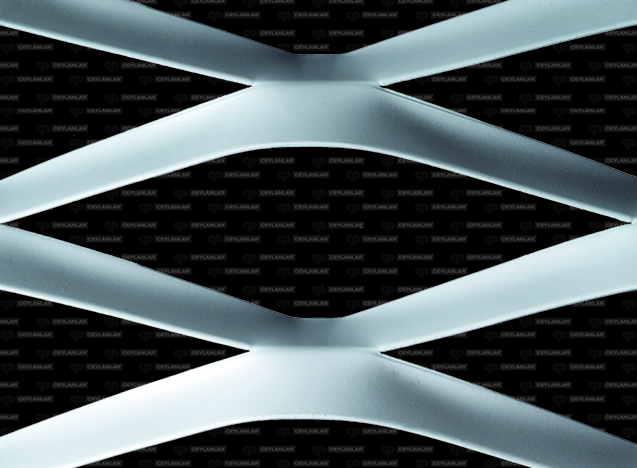

Expanded vs perforated metal, they differ greatly in many characteristics, and for example, firstly in terms of manufacturing process, expanded metal sheets are made out of plain sheet when they are subjected to a process that entails slitting and stretching the material into diamond-shaped mesh which is solid and lightweight this process leaves no wastage in materials, the end product has openings mainly ideal and the best fit to satisfy the applications of metal ventilation panels besides sunscreens; moreover, the security applications can get benefits from those panels to offer rigidity and robustness, The expanded metal advantages are too many and they can provide the Industrial metal panels and modern architectural metal cladding with valuable material to last in the long-run.

Conversely, perforated metal sheets are manufactured by undergoing a certain process known as punching holes into a solid surface which results in having hole patterns with high precision and different sizes to provide airflow and control. Since They are flexible they support a lot of decorative metal applications, mainly for acoustic solutions and many more, also, perforated metal uses extend to other areas such as interior paneling, façade shading and decoration plus filtration, as perforated sheets enjoy an accuracy in pattern making this has made them the most favored items to respond to the needs of diverse artistic facades and many others of branding elements this variety plus the technical enclosures they can provide uniformity steadily without any reservations.

Both materials are on demand for industrial metal sheet types, and their performance differs based on each project's unique requirements. Expanded metal sheets are known to provide noticeable strength-to-weight ratios and durability; this feature elevates them to be the most suitable product for walkways, heavy-load places, screens for protectiveness, and exterior façade shading. On the other hand, perforated metal sheets are known for provision of adequate control in light diffusion and airflow, and moreover in aesthetic demand, and therefore, they are considered highly favorable items in terms of cooling systems, acoustic panels, signage, and many more like interior feature walls. They are mainly used by architects and engineers to support different fields and to have creative building layers with transparency and adequate ventilation at the same time. The facade systems of ANB Metal Company greatly combine expanded and perforated metal to create patterns solutions with diversity to meet the intended performance goals and achieving sustainability with trendy features.

Selecting expanded metal sheets or perforated metal sheets is highly depended on many factors like the design intent, load capacities, airflow, and the striking visual expectations you are looking to reach. So getting familiar with those metal sheet comparisons will confidently ensure the right selection and application for many field using industrial metal panels, architectural metal cladding, and environmental designs with innovativeness.