We would be glad to offer you a high-quality product that will satisfy all your demands and needs

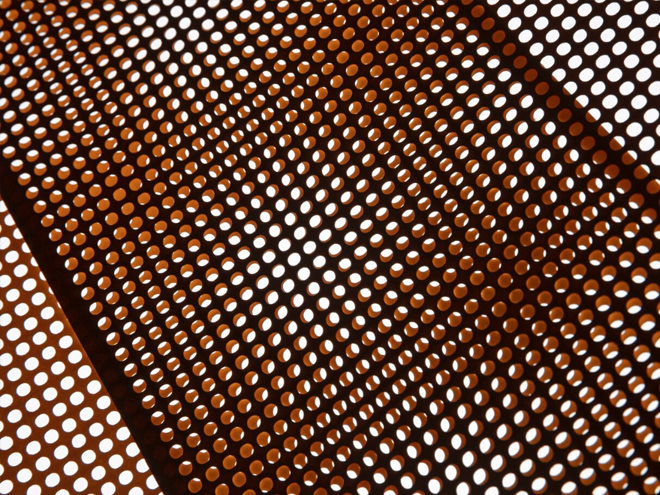

Diverse decorative perforated steel sheets come in colors and schemes of holes, giving you a distinctive choice for your projects.

The perforated steel, stainless steel perforated sheet and perforated aluminum sheet are highly customizable products with various variables such as material, thickness, hole diameter, hole shape, and hole spacing. Such a multifunctional setup is the reason for the wide applicability, as they can be used to make suspended ceilings, facades, sun control panels, and double-skin facade systems.

Metal Works customized to your goals

Our technical team not only solves the problems of acoustic, light transmission, and ventilation but also takes into account the aesthetic factors. Our production team can provide solutions that are consistent with budget, specific design, and installation plans so that you can successfully complete your perforated metal sheets or perforated panel projects.

To begin, it has been proved that perforated metal has become one of the best versatile and functional materials utilized in many fields like architecture and industrial applications. Perforated metal panels and sheets provide an extraordinary possibility in applications this can range from an attractive building look to practical advantages regarding ventilation and filtration and other industrial uses, At ANB Metal we can help you find your best matches

Now let's dive deeper and learn more about it.

We can surely define perforated metal as a piece of sheet metal that has been mechanically created or punched out to greatly produce a pattern of holes, slots, or any other forms from customization. The perforations required serve two main purposes role: decorations and functions with a wide variety of applications like standard ventilation, complex and custom-designed perforated metal utilized in the world of modern architecture.

What about the uses of perforated metals

ANB Metal can help you meet a wide range of applications:

Architectural applications: it is not surprising that those perforated metal panels have an extensiveness uses horizontally and vertically for example they are utilized functionally and aesthetically on modern buildings. They add a touch of elegance to the façades in addition to be used as sunshades providing a delicate natural sunlight

Industrial Application: Industrial perforated metal are on the rise in terms of demand in many fields like automobile, agriculture, and manufacturing sectors. It is also widely used in the filtration system industry, machinery guard's items, and as ventilating elements because they provide robustness and flexibility.

Interior & Exterior Design: A perforated metal can be custom-made in the field of interior and exterior design, offering great solutions for many applications like those in ceiling tiles or office partitions and decorative metal panels enhancing the aesthetic and functional values.

Enclosure & Fencing: Perforated metal mesh panels and sheet are greatly and widely used for the purposes of safety especially in commercial or residential blocks when they are adopted as fencing to provide robust enclosure to the intended areas.

ANB Metal provide a wide range of perforated metal types: