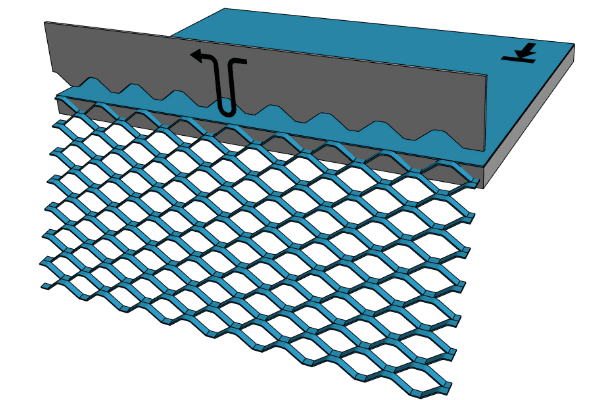

Expanded metal is produced by perforating and stretching metal plates/sheets. During the manufacturing process, no material is wasted, making it economical and environmentally friendly, thus serving as a good alternative to perforated metal.

Unique Advantages:

Decorative expanded metal, a new building decoration material typically made from aluminum or lightweight steel sheet after slitting and stretching processes, is offered with various powder-coated, anodized, and PVDF coatings. It is lightweight, has high load capacity, good corrosion resistance, and prevents aging. Not only does it add unique charm to buildings, but it also offers the best practical functions. Therefore, it is an environmentally friendly building decoration material popular among architectural designers.

We offer decorative expanded metal products in various materials, colors, and hole patterns for you to choose from. Just contact us, our professional designer will work with you to find the right expanded metal products and produce the best custom solutions together.

Features

Simply, expanded metal mesh is defined as a material of high versatility; it is always made from different types of metal sheet by applying a specific process that involves slitting and stretching the metal sheets to shape a specific patterns of strands with interconnectedness.

The process is qualified enough to gives an excellent, robust, and resistant product. This process is one of the most used among industries due to the enjoyment of certain characteristics: it is lightweight, resistant to climatic factors and adaptable. It has better ventilation because it allows enough light through patterns with maintenance of structural solidity.

Expanded metal mesh enjoys a lot of features which make it always on demand it's robust, flexible and multi-faceted, those features make it perfect to be utilized in many industries and applications.

Customizability: as known, every project has its special requirements and hence, expanded metal mesh can be widely customized into various designs and sizes in all material types

Sustainability: expanded metal can be coated and galvanized in order to make it more resistant to external harsh factors

Lightweight: as the expanded metal mesh name reveals its weight clearly this makes it easy to set up without any special expertise.

Economic value: when converting materials into expanded metal mesh this process result in zero wastage leaving no place for negative effect.

Expanded metal models come in many designs and functions:

A wide range of dimensions can be applied to expanded mesh sheets to meet any specific needs for any project.

Expanded metal sheet prices can greatly vary taking into account a lot of different factors like type of material type, its sizes and finally the desired finishing options. For example, aluminum mesh is typically affordable and costs less than other types like stainless steel or special types of steel.

To specify accurate pricing, you can consider the following factors:

Mesh Dimensions: the larger the sheets are the higher price is incurred.

Material Type: some materials are more expensive than others for example Stainless steel vs. mild steel.

Complexity of Pattern: when designs reqyure intricateness this might caue the costs to go up for the time and efforts they need.

Expanded metal mesh is a versatile solution due to structural distinction and adaptability it offers, in addition, it can fit and satisfy many different industries and applications, so expanded metal mesh is your best choice to respond to your diverse needs for industrial applications and decorative projects in architecture.